Preferred's commitment

-

Preferred Utilities was first company in the Northeast to convert its boilers to Bio-Residual™ Oil (BRO 500), which is produced from vegetable grease and animal fat, to power its 50,000 square foot facility in Danbury. They are also one of the first companies in Connecticut to convert its boilers to renewable fuel.

Senator Chris Murphy featured Preferred in a “Manufacturers Monday” and said “Preferred Utilities is leading the way in combating climate change by using alternative and renewable fuels to run their business and companies around the world are noticing.”

-

Preferred Utilities is committed to addressing the increasing regulations on carbon emissions with carbon neutral innovations and development of existing alternate fuels in partnership with other companies. We are contributing to “real world” alternative solutions to fossil fuels with low carbon emissions and high energy efficiency. Preferred also offers a robust internship program to high school and college students, exposing them to the latest in alternate fuel technology.

Energy Diversification

-

Preferred’s boiler room is able to fire natural gas, fuel oil, Renewable Fuel Oil, and Bio-Residual™ Oil (BRO 500). Preferred manufactures burners that can transition between these fuels at the flip of a switch. With concerns over sustainability and transitioning away from fossil fuel and high carbon emissions, we believe in a diversified approach that allows us to leverage technology of the past with solutions for the future. No one energy source is the answer, all renewable energy solutions must be applied where they make sense economically for the customer and for the nation.

“The energy market needs equipment and expertise that leverage the use of renewable energy,”

“The energy market needs equipment and expertise that leverage the use of renewable energy,”“Preferred takes a holistic approach to providing solutions, and adding solar to our building is a great demonstration of what we’re able to do. We’ve upgraded our property, and we’re investing in our community. And of course, we’re saving money, too.

- Dwayne Boulden, Preferred’s Vice President of Finance.

“There are no ‘silver bullets’ in the quest for sustainability with renewable energy. Intelligent, real, cost-effective diversification is the winner.”“If you are going to invest in a sustainable future, you have to look at a number of solutions, fuels, and energy sources. That’s why our combination of solar power generation and non-fossil, clean burning, ultra-low carbon emission BRO 500 is so successful, for Preferred Utilities and the planet.”

- David Bohn, Preferred’s President and CEOPreferred expanded its commitment to sustainability with the completion of a 209 kW solar panel installation at its Danbury facility in 2021. The solar panels generate approximately 70 percent of the building’s usage and support the town of Danbury’s grid when the plant is not in operation.

Renewable Fuels

-

While alternate and renewable fuel options have been touted as the way of the future, there has been a severe lack of innovation to develop renewable fuels into a sustainable option for facilities that use fossil fuels. The immense expense of replacing boiler room equipment at a facility such as a college campus to burn wood pellets or corn husks, along with the fact that these “fuels” cannot be supplied in large enough quantities to be a sustainable source of power, have rendered these types of temporary conversions to these renewable fuels, ultimately unsuccessful.

Traditional biofuels such as wood chips or pellets, while preferable to non-renewable fossil fuels, have still been found to have a negative environmental impact that can be problematic in many applications. A relatively recent innovation in the sector involves replacing wood chips with a fuel known as Renewable Fuel Oil (RFO) or “bio-oil” (also referred to as “liquid wood”). While this biofuel is more environmentally friendly, some users found it incompatible and difficult to use at first—but that is now changing. Boilers can be more easily modified to be compatible with liquid wood, and the cost is about one-tenth that of replacing the system.

Created by ENSYN Technologies Inc. out of Ontario Canada, liquid wood is produced using a thermochemical process called pyrolysis, in which wood is burned in excess of 500º C (in the absence of oxygen) and is transformed into a combustible liquid. Because there is no oxygen, the wood does not combust. It first becomes charcoal, and then further decomposes into gas and liquid. It behaves similarly to natural gas or crude oil except that it has much lower carbon emissions.

Customer Focus: Bates College

In 2017, Bates overhauled their campus heating system using Preferred’s real world approach. They weighed the idea of converting to wood chips, but they found that building a wood chipping plant and storing the wood chips on campus would have cost a startling $10 million upfront. When they realized they could achieve the same environmental benefits by converting to liquid wood instead of wood chips, while only spending $1 million on the conversion, the choice was easy. They implemented liquid wood as their primary heating source and saw their carbon footprint reduced by an astounding 83%.

-

Liquid wood still has the advantage of being a renewable wood-based resource. The raw wood used to create liquid wood is harvested from tree farms—and more trees can continuously be planted to replace those used for fuel oil.

An added advantage is that liquid wood is less cumbersome to store than wood chips or pellets. In order to utilize wood chips, the user must address two onerous tasks—turning the bulk wood into chips, and then storing the chips themselves until they are used. There is also the challenge of getting the wood chips or pellets to the burner as they are not often stored in the same location. The logistics involved in managing chipping and storage can lead to significant added costs, as Bates College in Maine discovered.

WHAT IS BIO-RESIDUAL OIL?One of the newest innovations in environmentally responsible fuel is Bio-Residual™ Oil (BRO 500). This renewable energy source has 85 percent lower emissions that typical fossil fuels and has the potential to reduce carbon emissions in the United States by thousands of tons per year.

Made by Renewable Energy Group (REG) in Ames, Iowa, Bio-Residual™ Oil (BRO 500) has the viscosity equivalency of No. 6 oil. It is made up of all the heavy hydrocarbons left over from the refining of biodiesel, which can be made from diverse biological materials such as agricultural waste, animal fats, and recycled cooking oil.

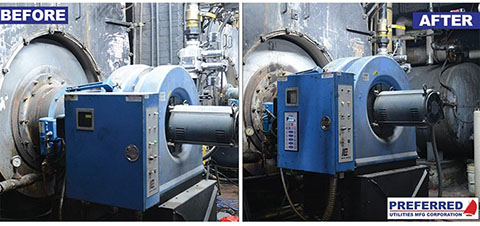

In 2018, Preferred’s engineers adapted the Preferred Rotary Cup burner, a legacy product found in many New York City boiler rooms today, to cleanly burn BRO 500 to power the manufacturing and engineering headquarters in Danbury, CT. In 2022, Preferred installed a new 10,000 gallon, double wall, above ground tank so we can continue burning BRO 500.

REG also produces biodiesel B20 for use in industrial applications and we have successfully converted a number of sites in New York City with existing 60 t0 70 year old Rotary Cup burners and our Fuel Oil Systems. Because BRO 500 and B20 have similar viscosities to oil, Preferrd’s fuel oil equipment is easily adapted to efficiently utilize this fuel.

The Preferred API Burner is UL listed with B20 in New York City, and is being implemented in housing and school applications for the city.

Low Emissions Solutions

-

Striking the balance between electrical consumption and NOx emissions is a challenge.

Although greenhouse gases are the chief focus of most sustainability goals, they are not the only emissions to consider. Industrial boilers also emit nitrogen oxide (NOx), which is a significant air pollutant and is the key component in smog. These NOx emissions are regulated by the EPA and state agencies, with standards becoming steadily tighter since the 1990s.

Unfortunately, decreasing NOx emissions means upping electrical usage—the lower the NOx, the more electricity required. This can be a source of concern for those looking at low-NOx burners. They face the tough choice of either getting a system with the lowest possible emissions while sacrificing significant electrical efficiency, or else using a higher emissions system (that might become obsolete in a few years if regulations continue to get stricter) in an attempt to save on electricity. This rock-and-a-hardplace dilemma is even tougher in states with high electrical costs such as Connecticut and Hawaii, or cities like New York City. Preferred has been able to implement a Low NOx, low electricity cost at multiple sites including Stapleton Houses in New York City.

-

Customer Focus: NYC Housing Authority

There are Preferred burners currently in active service for the New York City Housing Authority and the New York City Board of Education that are more than 60 years old.

The solution lies in the flexibility afforded by a new generation of low-NOx burners with configurable controls. These systems can be configured to meet current regulations or targets, while operating at the highest electrical efficiency possible. Should regulations ever change, the burner can easily be updated for the new target NOx levels.

Green Hydrogen & Gas Blending

Often, plants that make waste hydrogen will recycle it, blended it with natural gas, and burn it to power their industrial plants, such as wastewater or sewage treatment facilities, chemical facilities, and food processing facilities. This waste hydrogen is a byproduct of the reforming or refining process, not made from fossil fuels. Therefore, it is considered “green” as no emissions were spent to create it.

Preferred Special Combustion Division specializes in gas blending systems and combustion systems for alternate fuels created by recycling waste gas. This waste gases are a byproduct of the reforming or refining process and not made from fossil fuels. Therefore, they are “green” as no emissions were spent to create them.

Controls & Automation

-

Preferred Instruments and Controls are designed for boiler rooms to monitor and automate for optimum performance, safety, and security. Aged mechanical systems in the boiler room lack the accuracy of modern automated systems, creating inefficiencies in energy and fuel expenditures. To solve that, Preferred’s has created products to automate every function in the boiler room.

Customer Focus: Yeshiva University & Columbia Teachers College

At Yeshiva University, Preferred installed the FlexFit, and thanks to the reduced consumption of fuel (5% overall), the university was able to qualify for a range of energy incentives from their utility company, and these incentives alone covered almost the entire cost of the new control system.

The Preferred FlexFit Linkageless Controller can be installed to convert a linkage system (mechanical) to a linkagless system (automated) without gutting the boiler room. The FlexFit Linkageless Controller brings automatic control to your burner with an integrated flame safeguard system by plugging directly into Fireye E110 and Honeywell RM7800L wiring bases, eliminating extensive re-wiring and installation time. A NYSERDA study, using the FlexFit, recommends linkageless control systems for energy savings!

-

Columbia Teacher’s College also qualified for rebates after installing the Burnermate Universal Control System (BMU), a high technology total boiler control system. Linkageless control with optional oxygen trim provides fuel savings. Control of Variable Speed Drives provides the electricity savings.

In addition to flame safeguard and combustion control, the BMU includes optional draft control and feedwater control. The BMU allows for energy efficiencies previously unknown in the boiler room.

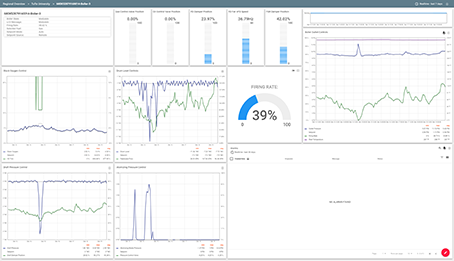

The Columbia facility upgrade also included the Preferred Cloud Remote Monitoring System. The Preferred Cloud securely monitors and creates optimizing analytics for facilities. This installation allows the facility’s manager to view their equipment on a secure webpage and send alerts and updates to mobile phones or computers. Eliminating errors, inefficiencies, and security concerns in the boiler room allows 24/7 surveillance, no surprises and energy savings in the form of electric and fuel costs reduction.

The Future

- Addressing today’s energy challenges takes creativity and the understanding that one size does not fit all applications. Preferred’s diverse team and leadership is committed to changing the world in the ways we can – providing solutions to help ourselves and our customers reach their sustainability goals. We lead by example and look forward to many more years of dauntless innovation.